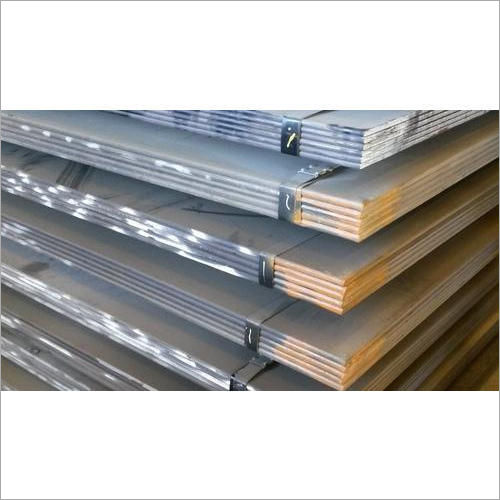

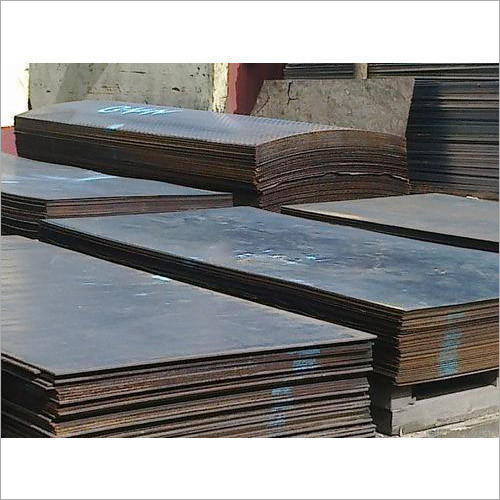

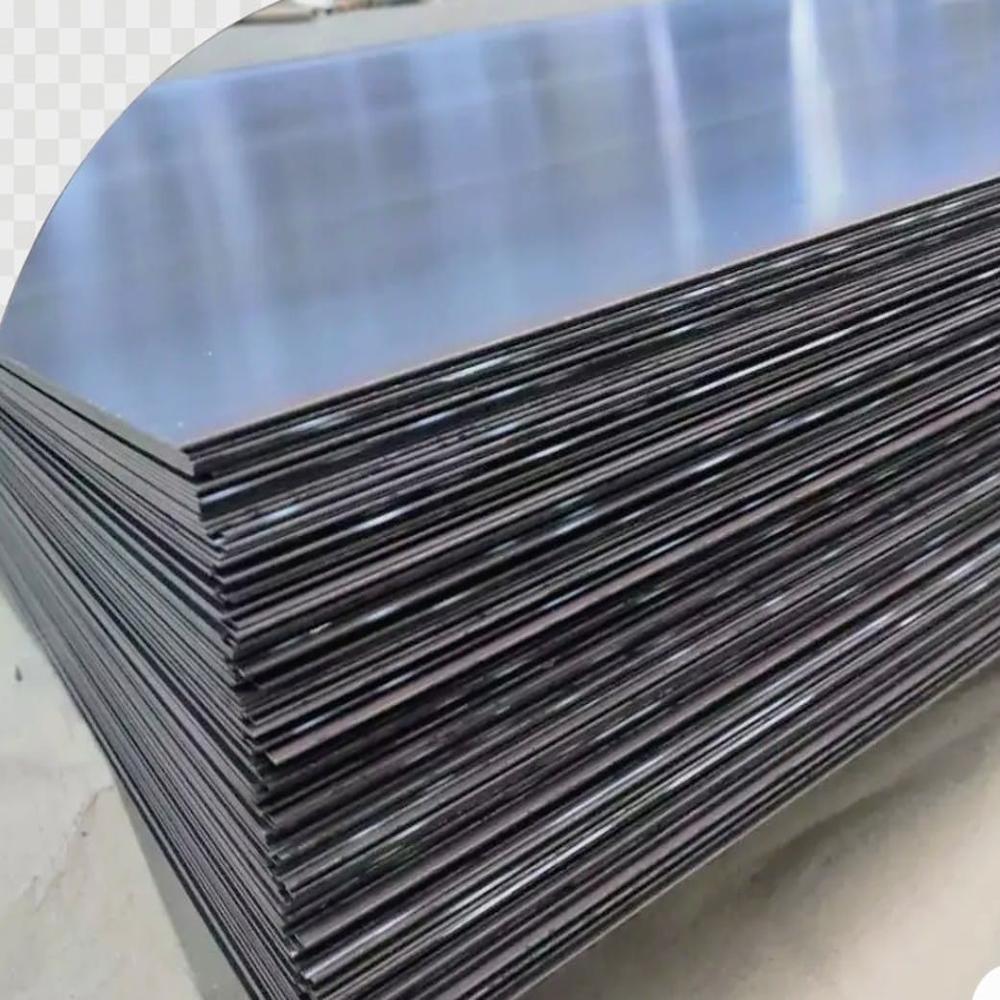

HR MS Plate

Price 51.0 INR/ Kilograms

MOQ : 500 Tons, Ton

HR MS Plate Specification

- Product Name

- Other

- Steel Type

- Mild Steel

- Steel Product Type

- Steel Plates

- Grade

- E-250,E350,E-400

- Thickness

- 2.5mm TO 32mm Millimeter (mm)

- Shape

- Plate

- Steel Standard

- Other

- Surface

- MS

- Composition

- MS

- Application

- Construction

- Dimension (L*W*H)

- MM Millimeter (mm)

- Weight

- KG Kilograms (kg)

- Color

- Black

- Material Grade

- 2062

HR MS Plate Trade Information

- Minimum Order Quantity

- 500 Tons, Ton

- FOB Port

- GHAZIABAD

- Supply Ability

- 1000 Tons, Ton Per Day

- Delivery Time

- 1 Days

- Sample Available

- No

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Domestic Market

- All India

- Certifications

- avilable

About HR MS Plate

We are a trusted name among the manufacturers of Industrial HR MS Plate in the market. It can be provided with surface treatment choices of coated, galvanized and others. Some of the features of our Industrial HR MS Plate include optimum quality and finishing. It is available for use in construction, shipbuilding, machinery manufacturing, bridges and other areas.

Product details

|

Surface Treatment |

Cold Rolled, Hot Rolled |

|

Type |

ms sheet, ms plate, cr sheet |

Wide Range of Thickness and Grades

HR MS Plates cater to varied construction requirements by offering thicknesses ranging from 2.5mm to 32mm and multiple grades (E-250, E-350, E-400). This flexibility equips engineers and builders with suitable options for diverse project specifications, enhancing structural strength and longevity.

Reliable Galvanized Surface

The galvanized finish on these mild steel plates acts as a protective barrier against corrosion, prolonging the life of the product even in challenging environments. This added protection reduces maintenance needs and preserves the plates structural integrity over time.

FAQs of HR MS Plate:

Q: How are HR MS Plates with galvanized surfaces used in construction projects?

A: HR MS Plates are commonly employed in construction to provide durable frameworks, reinforcements, and support structures. The galvanized surface protects against rust and corrosion, making them ideal for outdoor and high-moisture environments.Q: What are the benefits of choosing HR MS Plates in grades E-250, E-350, and E-400?

A: Selecting from various grades allows you to match the steels strength and flexibility requirements for specific applications. E-250 offers standard strength, E-350 provides higher yield, and E-400 delivers enhanced durability for more demanding purposes.Q: Where are galvanized HR MS Plates typically sourced and supplied in India?

A: These plates are distributed by established exporters, fabricators, service providers, suppliers, traders, and wholesalers across India, ensuring wide availability and reliable supply chains for construction and industrial sectors.Q: When is it ideal to use HR MS Plates of thickness between 2.5mm to 32mm?

A: The choice of thickness depends on the structural load and application. Thinner plates (2.5mm6mm) are suitable for lighter fabrication, while thicker ones (above 6mm) are preferred for heavy-duty frameworks and load-bearing structures.Q: What is the process behind galvanizing HR MS Plates?

A: The galvanization process involves coating the mild steel plates with a protective layer of zinc, which shields them from moisture and environmental elements, effectively minimizing the risk of corrosion and prolonging their lifespan.Q: How does using HR MS Plates benefit fabricators and construction companies?

A: HR MS Plates offer easy workability, consistent quality, and enhanced corrosion resistance, allowing fabricators and builders to efficiently create robust, long-lasting structures with reduced maintenance costs.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in HR Mild Steel Plate Category

HR PLATE and Sheet

Price 51.0 INR / Kilograms

Minimum Order Quantity : 500

Steel Type : Mild Steel

Steel Product Type : Steel Plates

Grade : E250,E350,E400

Thickness : 2.5mm TO 32mm Millimeter (mm)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry