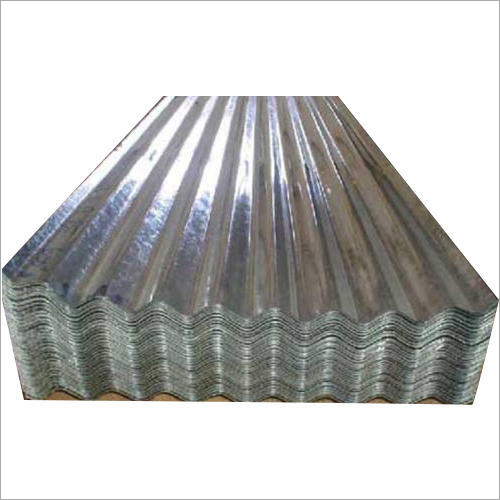

Galvanized Iron Corrugated Sheet

Price 73.0 INR/ Kilograms

Galvanized Iron Corrugated Sheet Specification

- Heat Resistance

- Yes

- Product Form

- Corrugated sheet

- Coating Type

- Galvanized coating

- Recyclable

- Yes

- Hardness

- Medium to high hardness

- Tensile Strength

- High tensile strength Megapascals (MPa )

- Corrosion Resistant

- Yes

- Material Composition %

- Galvanized iron

- Steel Type

- Galvanized steel

- Steel Product Type

- Sheet

- Grade

- Commercial quality

- Thickness

- Variable thickness (commonly 0.4mm to 1.2mm) Millimeter (mm)

- Steel Standard

- Conforms to ISO standards

- Surface

- Smooth and corrugated

- Composition

- Iron and zinc

- Application

- Other

- Dimension (L*W*H)

- Standard dimensions available Inch (in)

- Color

- Silver

- Material Grade

- Industrial grade

Galvanized Iron Corrugated Sheet Trade Information

- Minimum Order Quantity

- 500 Kilograms

- Supply Ability

- 100000 Kilograms Per Day

- Delivery Time

- 1-2 Days

About Galvanized Iron Corrugated Sheet

Tamper Proof Galvanized Iron Corrugated Sheet is one of the widely demanded sheet offered by us in the market. It is known for being tamper proof, durable coating, water proof, corrosion resistant, architectural attractiveness and durability. Tamper Proof Galvanized Iron Corrugated Sheet is thoroughly tested on different parameters prior to the final dispatch.

Product details

|

Thickness of Sheet |

0.45 mm |

|

Features |

Water Proof, Tamper Proof, Corrosion Resistant |

|

Manufacturing Technique |

Cold Rolled |

|

Surface Treatment |

Galvanised |

|

Area of Application |

Residential & Commercial |

Superior Corrosion Resistance

Galvanized iron corrugated sheets are formulated with a robust zinc coating, making them highly resistant to rust and environmental wear. This quality ensures long-term durability, especially in outdoor and industrial settings, thereby minimizing maintenance costs and extending structural lifespan.

High Strength and Versatile Applications

These corrugated sheets boast a high tensile strength, moderate heat resistance, and medium to high hardness. They are suitable for roofing, siding, fencing, and fabrication. The industrial grade material stands up well to mechanical stress, providing reliable performance in demanding conditions.

Environmentally Friendly and Recyclable

The use of iron and zinc not only enhances the sheet's physical properties but also ensures full recyclability. By choosing galvanized corrugated sheets, customers support sustainable construction practices while benefiting from robust protection and practical versatility.

FAQ's of Galvanized Iron Corrugated Sheet:

Q: How does the galvanized coating protect the corrugated sheet from corrosion?

A: The galvanized coating, made from zinc, provides a barrier against moisture, oxygen, and other corrosive elements. This effectively prevents rust formation, thereby extending the sheet's operational life in humid or harsh environments.Q: What are the standard thickness options available for galvanized corrugated sheets?

A: Galvanized iron corrugated sheets are typically available in variable thickness, most commonly ranging from 0.4mm to 1.2mm. These options allow users to select the suitable thickness based on structural and environmental requirements.Q: When is it ideal to use galvanized iron corrugated sheets?

A: These sheets are ideal for use in applications requiring strong, corrosion-resistant roofing or siding, particularly in industrial, agricultural, and outdoor installations. Their high tensile strength and moderate heat resistance make them suitable for demanding conditions.Q: Where can I source galvanized iron corrugated sheets in India?

A: You can obtain these sheets from exporters, fabricators, service providers, suppliers, traders, and wholesalers across India. They are widely available for various industrial, commercial, or residential projects.Q: What is the process of galvanizing the iron sheets?

A: Galvanizing involves coating iron sheets with a layer of zinc, usually by hot-dipping. This process forms a protective film over the sheet's surface, enhancing its corrosion resistance and durability.Q: How does the composition of iron and zinc affect the sheet's performance?

A: The combination of iron's inherent strength and zinc's corrosion resistance delivers a product that boasts high tensile strength, durability, and reduced maintenance, making it reliable for structural applications.Q: What are the main benefits of using galvanized iron corrugated sheets?

A: Galvanized iron corrugated sheets offer excellent corrosion resistance, high tensile strength, recyclability, and moderate heat resistance, making them sustainable and cost-effective solutions for long-term usage in building and structural projects.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Galvanized Corrugated Sheet Category

Corrosion Resistant Galvanized Corrugated Sheet

Price 68 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Application : Construction

Steel Product Type : Steel Plates

Grade : Industrial

Shape : Plate

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry